Vance Manufacturing's Coating Options

Information and Comparison

One question we often receive is, "What is the difference between the different coatings that you offer?" This question is important, and selecting the correct option could make a big difference for your product for years to come. When you're researching and deciding on aluminum coatings for Vance jack plates, Vance kick-up plates, Vance hydraulic kick-up plates, Vance hydraulic jack plates, Vance drop-down plates, Vance foot throttles and other Vance Manufacturing products and accessories, use the guide below to help. These options are almost always in stock and ready to ship to your door.

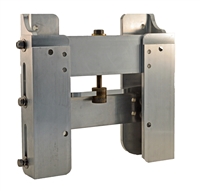

Raw Aluminum/No Coating

The Raw Aluminum option for Vance Manufacturing products is just as stated; no coating or corrosion-resistant coatings are applied. This is the most basic option we offer and is great for situations when you're on a budget, you don't desire color/coatings and you will always be using your Vance product in a freshwater environment. This option does not have an upcharge.

- No coating and no protection against elements

- Aluminum is sometimes dull to shiny in color

- Best for people on a strict budget and for use in freshwater applications

- Not recommended for saltwater or brackish water applications

- Will oxidize in saltwater and break down

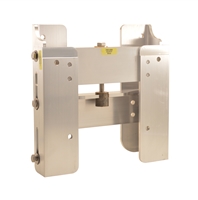

Clear Anodize Coating

The Clear Anodize option for Vance Manufacturing products is a good corrosion-resistant inhibitor for saltwater and brackish water applications. This is an aircraft-grade coating used to prevent the corrosion and breakdown of materials in a corrosive environment. When Clear Anodize is chosen, the color is similar to a clear coat and sometimes leaves a hint of a golden color for visual purposes. This option does have an upcharge on most Vance Manufacturing items.

- Good salt water corrosion resistance

- Does not scratch or chip off

- Aluminum Clear Coat Color has a slight gold tint

- Recommended for offshore and brackish water unless black color is desired look below

- Coating applied in tank while pieces are disassembled to entire surface is coated

Hard Black Anodizing

The Hard Black Anodizing option for Vance Manufacturing products is an excellent corrosion resistant inhibitor for salt water and brackish water applications. This is an aircraft grade coating used to prevent and elongate the corrosion breakdown of the materials in a corrosive environment. When Hard Black Anodize is chosen, the color is similar to a Black Paint job or Black Powder Coating. This is a favorite for duck hunters and offshore fishermen! This option does have an up charge on most Vance Manufacturing items.

- Excellent salt water corrosion resistance

- Black Color, extremely durable

- Preferred by duck hunters and offshore fishermen

- Does not scratch or chip off

- Coating applied in tank while pieces are disassembled to entire surface is coated

Black Powder Coating

The Black Powder Coating option for Vance Manufacturing products offers zero to little corrosion resistance for salt water and brackish water applications. This is a sprayed on coating and we prep the material's surface using alodine. This will help harden the surface and prevent chipping and breakdown of the powder coating. When Black Powder Coating is chosen, the color is similar to a Black Paint Job with semi gloss to gloss look. This option does have an up charge on most Vance Manufacturing items.

- No Salt Water Corrosion Resistance

- Black Color, Glossy finish

- Susceptible to scratches and chipping

- Not recommended for salt or brackish water

- Alodining on our material helps to elongate the coating life

.jpg)